MecaRoll

The MecaRoll system is used as a safe connecting system in the open area between the roll store, stripping area and the automatic reelstand. It effectively satisfies the special conditions with respect to the safety of personnel and the careful, protective transport of the rolls.

Guide rails

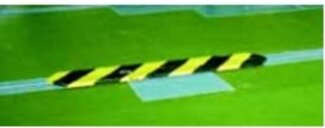

The guide rail comprises 2 U-shaped steel profiles mounted on a hollow profile. Two flat steel cover profiles close the rail off at the top. A duplex roller chain transfers the drive force non-positively by friction to the skid at the roll trolley. The chain is guided by a plastic slide rail. Each rail section comprises a drive and a tensioning station. The frequency-controlled hollow shaft gear motor can be fitted with a pulse transmitter for the accurate positioning of the roll or the roll trolley. The system with the special friction skid drive concept represents a technically safe solution for connecting different plant components for transporting rolls in an area accessed by personnel.

Turntables

The turntables provide the MecaRoll conveyor system with the flexibility for sending rolls to a predefined address. Simultaneously the turntables enable the roll to be brought to a defined winding direction. The turntable, mounted on a sturdy slewing ring gear is equipped with drives for the 90°/180° rotation and for the builtin MecaRoll rail. The arriving roll trolley is stopped in the centre of the turntable and transported on in the new direction according to address.

Roll Trolley

The roll trolley represents the means of transport in the MecaRoll conveyor system. The basin-shaped platform is designed for the careful reception of the paper rolls. The rolls can already be prepared for the pasting operation in the reelstand. The roll trolley is fitted with ball bearing mounted casters. The drive from the roller chain is non-positive by means of a friction skid. A technically safe solution for transporting rolls in an area accessed by personnel.