Stripping Assist

The stripping assist has a central function in the roll transport. In addition to the actual stripping this position is also ideally suited for pasting preparation, checking the roll condition, barcode input, checking the roll gross and net weight plus the perfect alignment of the roll for the following automatic processes.

Stripping Assist

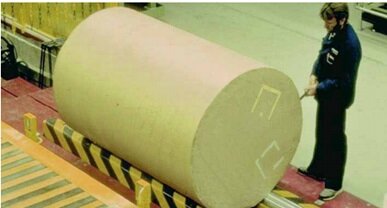

The stripping device serves to assist the operator to unpack the roll simply and with minimum effort. It comprises a base frame, a lifting unit with integrated support rollers and a MecaRoll guiding rail. The lifting and rotary movement of the support rollers is provided by a hydraulic cylinder and a hydraulic motor. Only one support roller is driven, the other freewheels.

Function sequence

A MecaRoll roll trolley transports the paper roll to the stripping assist. The two support rollers are raised as soon as the roll is detected in the stripping assist. This lifting action frees the MecaRoll trolley which can run back to the previous position. The operator at the stripping assist cuts open the packaging and winds it during the rotary movement of the roll. The rotary movement is activated by a foot switch. The winding is carried out manually. When the roll is completely stripped, prepared and aligned it is carefully and parallel lowered down in the Vshaped platform of the MecaRoll trolley.